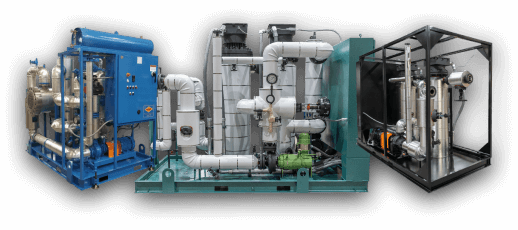

How DVS Heat Transfer Systems Support Lifecycle Sustainability from Design to Disposal

Developments in Heat Transfer Solutions: What You Need to Know for Optimum Efficiency

Technologies in Heat transfer systems are changing efficiency throughout various markets. Advanced products like graphene and nanofluids assure substantial renovations in thermal conductivity. The combination of IoT and equipment knowing uses possibilities for real-time monitoring and enhanced energy efficiency. The landscape of thermal monitoring is swiftly progressing. Recognizing these developments is vital for accomplishing suitable system efficiency and sustainability in the future. What certain advancements are shaping this improvement?

Emerging Products for Enhanced Heat Transfer

Advanced Heat Exchanger Layouts

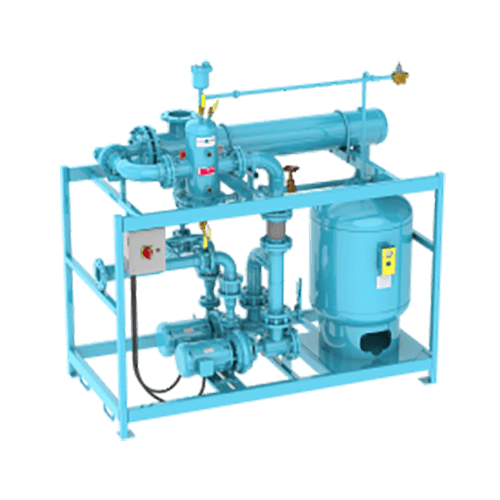

While traditional Heat exchangers have actually offered their function in different applications, advanced layouts are now arising to fulfill the raising demands for effectiveness and performance. These ingenious styles, such as plate, shell-and-tube, and finned-tube Heat exchangers, incorporate enhanced area and boosted circulation patterns to increase thermal transfer prices. Additionally, small designs allow for reduced area needs without compromising effectiveness. Advanced materials, such as composites and corrosion-resistant alloys, in addition improve sturdiness and efficiency under severe conditions. Simulation innovations and computational fluid characteristics are significantly used to improve these layouts, making certain peak Heat transfer attributes. As sectors look for to lessen energy intake and take full advantage of output, the adoption of sophisticated Heat exchanger styles is crucial in accomplishing these objectives.

The Role of Nanotechnology in Heat Transfer

Nanotechnology plays a crucial function in enhancing thermal conductivity within Heat transfer systems. By controling materials at the nanoscale, scientists have actually attained significant improvements in power efficiency. These innovations not just optimize efficiency yet likewise add to more sustainable power services.

Boosted Thermal Conductivity

Significant advancements in thermal conductivity have emerged via the application of nanotechnology, transforming Heat transfer systems throughout numerous sectors. By incorporating nanoparticles into Heat transfer liquids and products, researchers have actually accomplished amazing increases in thermal conductivity. These nanoparticles, such as carbon nanotubes, graphene, and metal oxides, boost the Heat transfer residential properties because of their high surface and one-of-a-kind thermal attributes. The resulting composites show enhanced performance in applications ranging from electronics cooling systems to eco-friendly power modern technologies. Furthermore, the capacity to tailor the size, shape, and composition of nanoparticles enables maximized thermal monitoring remedies. Consequently, nanotechnology proceeds to play a crucial role in the growth of a lot more effective and reliable Heat transfer systems, leading the way for enhanced commercial applications.

Power Effectiveness Improvements

Combination of IoT in Heat Transfer Systems

The assimilation of IoT in Heat transfer systems presents the application of smart sensing units that boost functional effectiveness. These sensing units enable real-time information tracking, enabling prompt modifications and optimizations. This technological advancement has the prospective to significantly boost efficiency and power administration in Heat transfer applications.

Smart Sensors Implementation

As Heat transfer systems develop, the integration of wise sensors via the Internet of Points website link (IoT) has actually become a transformative method. These sensors allow real-time monitoring of circulation, pressure, and temperature prices, enhancing system efficiency and integrity. By gathering and sending data, they help with aggressive maintenance, minimizing the threat of system failings. In addition, wise sensing units contribute to energy financial savings by refining operational criteria based on ecological problems. Their capacity to analyze trends and anomalies allows for educated decision-making, guaranteeing peak efficiency of Heat transfer systems. As markets significantly adopt this innovation, the execution of wise sensors stands to transform how Heat transfer systems are handled, leading the way for better sustainability and improved efficiency results.

Real-Time Information Monitoring

Just how can real-time data keeping an eye on improve the performance of Heat transfer systems? By incorporating Net of Things (IoT) modern technology, Heat transfer systems can utilize continual information collection from smart sensing units. This real-time monitoring enables prompt evaluation of circulation, temperature, and pressure prices, enabling operators to determine inadequacies promptly. Changes can be made to maximize performance, decrease power usage, and extend tools lifespan. Furthermore, anticipating maintenance can be implemented, lessening unforeseen downtime and costly repairs. The ability to visualize efficiency metrics through control panels improves decision-making, promoting a proactive technique to system monitoring. Eventually, real-time information checking not only improves operational efficiency however also adds to sustainability objectives within industrial processes.

Power Efficiency and Sustainability Trends

Power performance and sustainability fads are reshaping the landscape of Heat transfer systems, driving development and compliance across various industries. Organizations are progressively prioritizing energy-efficient styles to minimize operational prices and reduce environmental influences. The combination of eco-friendly power sources is ending up being more widespread, making it possible for Heat transfer systems to run sustainably while fulfilling regulative demands. In addition, developments in technologies and products promote reduced energy consumption and improve general performance. Lifecycle evaluations are additionally gaining traction, enabling firms to evaluate the environmental effect of Heat transfer systems from manufacturing to disposal. This emphasis on sustainability not just great post to read supports corporate responsibility however additionally positions organizations competitively in a market where consumers significantly favor green services. Consequently, power performance and sustainability stay vital considerations for future developments in Heat transfer modern technology.

Technologies in Thermal Monitoring Solutions

While the demand for effective Heat transfer continues to climb, advancements in thermal administration services are emerging to attend to both efficiency and sustainability difficulties. Advanced products, such as phase change materials and nanofluids, are being developed to boost Heat transfer efficiency - DVS Heat Transfer Systems. These products website link boost thermal conductivity and enable far better temperature level policy in numerous applications. Additionally, modern technologies like energetic thermal control systems are gaining grip, making it possible for real-time adjustments to manage Heat flow efficiently. These systems add to power cost savings and reduce the ecological effect of thermal processes. Furthermore, the combination of IoT in thermal management facilitates surveillance and anticipating maintenance, making certain maximized performance and durability of Heat transfer systems. Overall, these innovations represent substantial strides towards even more lasting thermal management methods

Future Directions in Heat Transfer Technology

Arising improvements in thermal management options signal an encouraging future for Heat transfer modern technology. Scientists are increasingly concentrating on creating materials with remarkable thermal conductivity and boosted energy effectiveness. Technologies such as nanofluids, which include suspended nanoparticles, supply considerable improvements in Heat transfer performance. In addition, the combination of smart materials that adjust to differing temperature problems is gaining grip, permitting even more reliable and responsive systems. The rise of additive manufacturing techniques is additionally allowing the layout of complex Heat exchanger geometries that optimize fluid flow. The execution of equipment knowing algorithms is prepared for to change the optimization of Heat transfer systems, assisting in anticipating maintenance and performance improvement. Jointly, these advancements are positioned to transform the landscape of Heat transfer technologies in various markets.

Regularly Asked Inquiries

Just how Do I Select the Right Heat Transfer System for My Application?

Selecting the appropriate Heat transfer system involves evaluating application requirements, including temperature ranges, fluid properties, and effectiveness demands. Assessing system kinds, upkeep factors to consider, and cost-effectiveness also plays an essential duty in making a notified choice.

What Are the Upkeep Demands for Advanced Heat Exchangers?

Upkeep needs for innovative Heat exchangers generally consist of routine inspections, keeping track of for leakages, cleansing of surfaces, and ensuring ideal circulation prices. Abiding by supplier guidelines warranties effective procedure and extends the equipment's life-span.

How Do Ecological Aspects Influence Heat Transfer Performance?

Environmental aspects considerably influence Heat transfer effectiveness. Variations in moisture, air flow, and temperature level influence thermal conductivity and convective Heat transfer, inevitably affecting system performance and necessitating consideration throughout the style and operation of Heat transfer systems.

What Security Criteria Apply to Heat Transfer Equipments?

Security standards for Heat transfer systems generally consist of standards from organizations such as ASME and ASTM. DVS Heat Transfer Systems. These criteria address materials, style, and operational practices to ensure integrity, efficiency, and protection versus hazards in numerous applications

Just How Can I Troubleshoot Common Heat Transfer System Issues?

Troubleshooting common Heat transfer system issues involves looking for leaks, ensuring correct liquid circulation, checking insulation integrity, and confirming temperature level differentials. Determining these variables can help maintain system effectiveness and prevent further problems.

Nanotechnology plays a necessary duty in boosting thermal conductivity within Heat transfer systems. Significant developments in thermal conductivity have actually arised with the application of nanotechnology, transforming Heat transfer systems across numerous sectors. Innovations in thermal conductivity through nanotechnology have paved the way for exceptional enhancements in power efficiency within Heat transfer systems. Energy efficiency and sustainability trends are improving the landscape of Heat transfer systems, driving innovation and conformity across various markets. The combination of IoT in thermal administration promotes surveillance and anticipating maintenance, ensuring enhanced performance and durability of Heat transfer systems.